Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

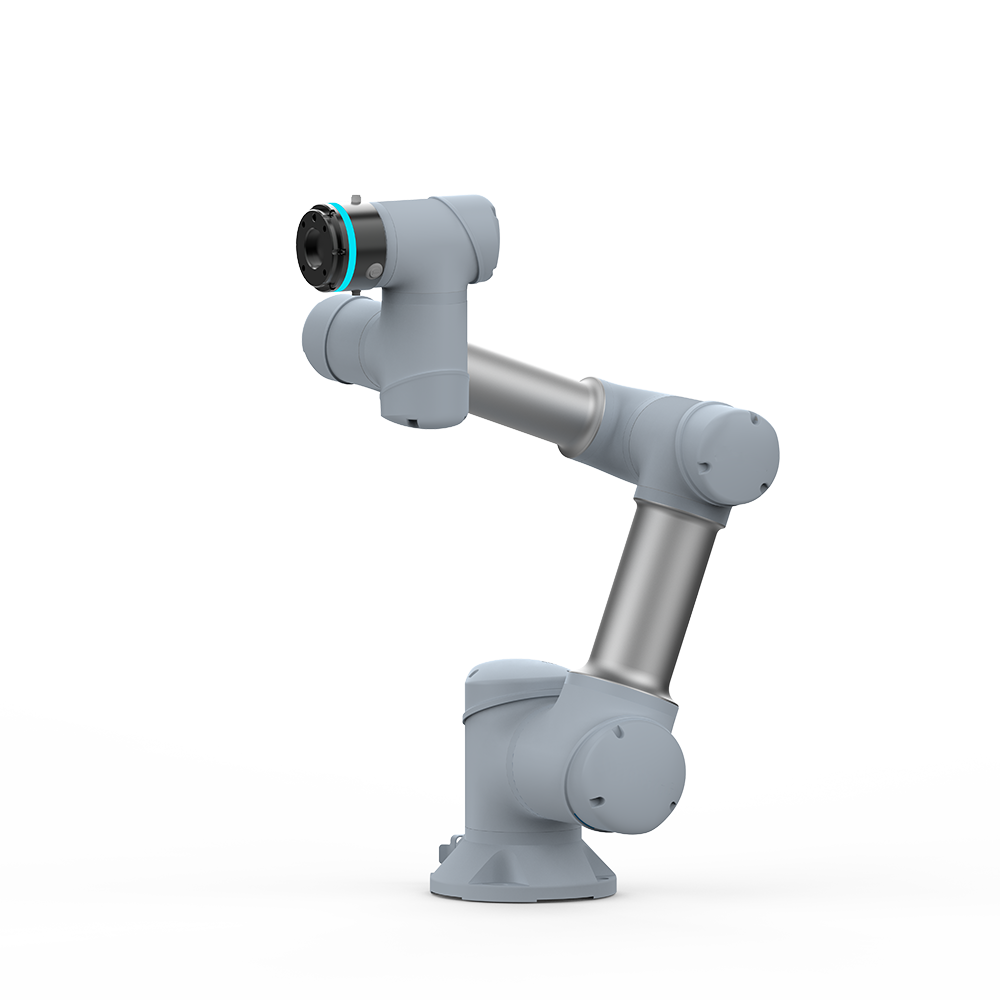

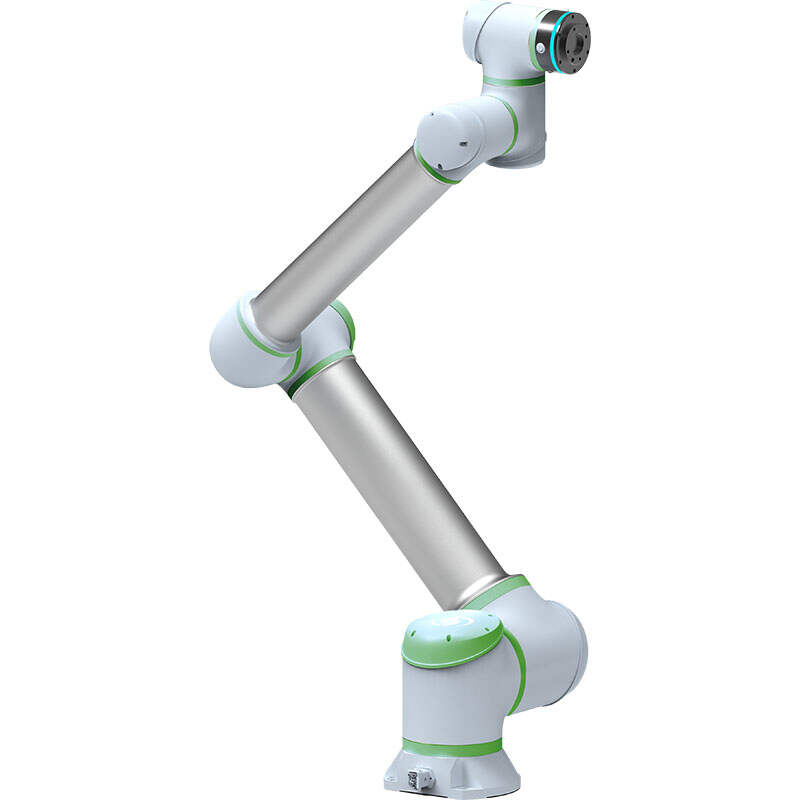

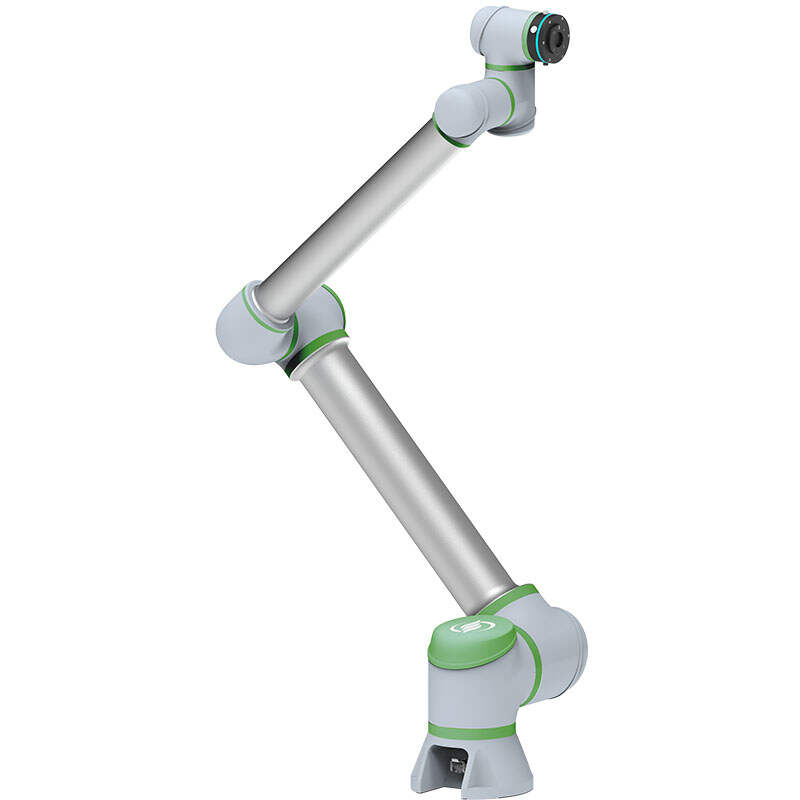

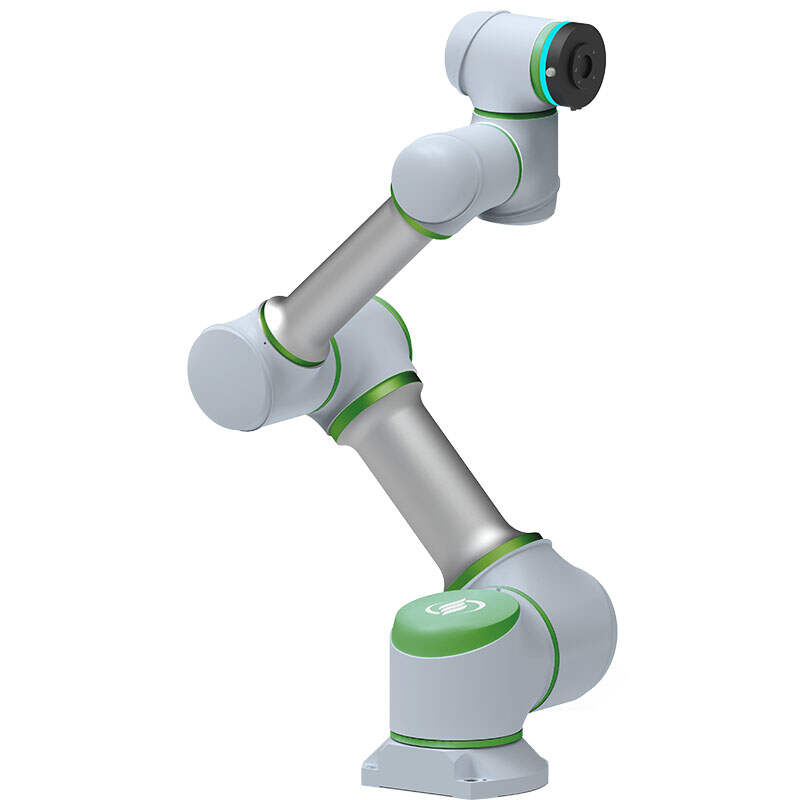

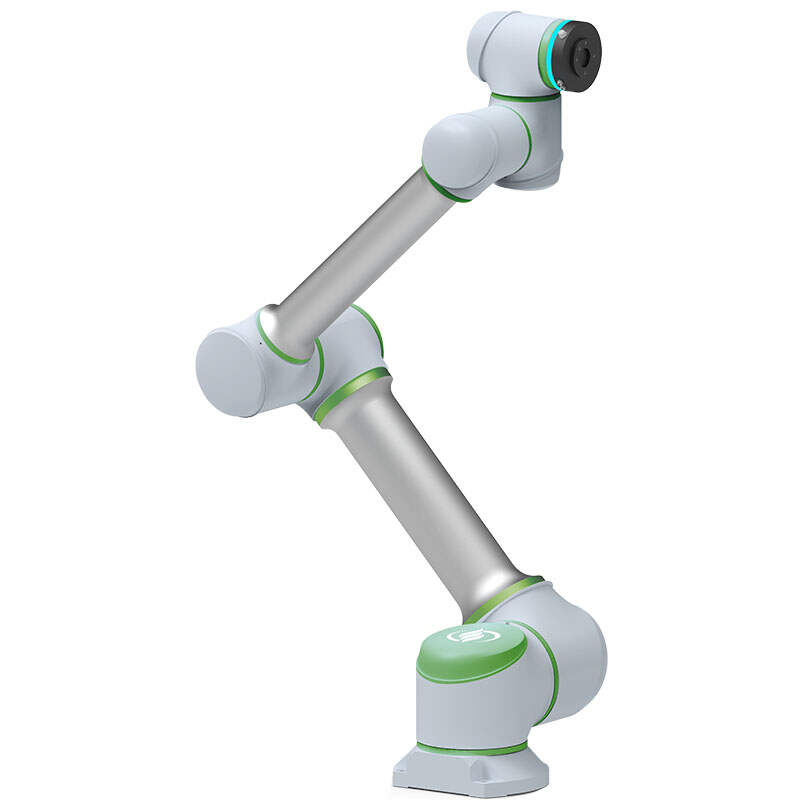

Standard 6-Axis Cobots X3-618

The X3-618 from the X Series Cobots is a standard 6-axis cobot designed to cater to various industrial needs efficiently and safely. With its compact size, advanced control capabilities, and collaborative safety features, it stands out as a versatile solution for a wide range of applications.

- Product Details

-

Download

Product Description

The X3-618 is a state-of-the-art cobot meticulously engineered to meet the demands of modern manufacturing environments. It boasts a sleek design and compact form factor, making it suitable for tight spaces without compromising on performance. Equipped with the latest AUCTECH controller, it ensures precise and reliable operation while maintaining human safety as a top priority.

Product Specification

|

Standard 6 Axes Cobot Parameters |

|

|

|

|

X3-618 |

|

|

Max Payload |

3kg |

|

|

Degress of Freedom |

6 |

|

|

Max TCP Speed |

1.0m/s |

|

|

Max Straight-line Speed |

0.8m/s |

|

|

Reach |

618mm |

|

|

Repeatability |

±0.02mm |

|

|

Joint |

range of motion |

Max Speed |

|

J6 |

±360° |

225°/s |

|

J5 |

±360° |

225°/s |

|

J4 |

±360° |

225°/s |

|

J3 |

±360° |

225°/s |

|

J2 |

±360° |

225°/s |

|

J1 |

±360° |

225°/s |

|

Tool Interface |

GB/T 14468.1-50-4-M6(eqv ISO 9409-1) |

|

|

End Joint I/O |

2 Dig I/O, 24V, 0.6A |

|

|

Power Supply |

100-240VAC 47-63Hz 10A |

|

|

Power Consumption |

Typical Power |

|

|

Installation |

Installed in any Direction |

|

|

IP Class |

IP54 |

|

|

Ambient |

-10℃-45℃ |

|

|

Storage |

-40℃-55℃ |

|

|

Robot Dimensions |

769x315x150mm |

|

|

Robot Package Size |

532x431x330mm |

|

|

Net/Gross Weight |

13kg/20kg |

|

Product Features and Advantages

1. Safety: Certified by TUV, the X3-618 incorporates 16 advanced safety functions, including collision detection and power monitoring, enabling seamless collaboration between humans and robots while ensuring utmost safety.

2. Smart Operation: With the addition of multiple scenario software packages and support for various external interfaces (DI, DO, AI/O), the X3-618 offers intelligent operation tailored to specific tasks. It also supports cloud-based monitoring and remote OTA upgrades for enhanced efficiency and convenience.

3. Versatile Application: The cobot is equipped with 2D and 3D visual depth compatibility, allowing it to adapt to diverse application scenarios. Its robust power control and comprehensive ecological support facilitate multi-application development, catering to evolving industrial needs.

4. Easy Maintenance: Featuring Traction Teach Programming: The X3-618 simplifies programming tasks, reducing limitations for users. Its user-friendly interface and streamlined maintenance processes ensure minimal downtime and maximum productivity.

5. Lightweight and Portable: Despite its high payload capacity, the X3-618 boasts a remarkable load-to-weight ratio of up to 1:2.44. The adoption of a new generation of control cabinets results in a significant reduction in size and weight, enhancing portability and flexibility in deployment.

6. Energy Efficiency: With a power consumption as low as 200W and no need for lubricating oil replacement, the X3-618 embodies eco-friendly operation, reducing operational costs and environmental impact.

Download

-

X-Series Cobot catalog of AUCTECH V3.0.pdf